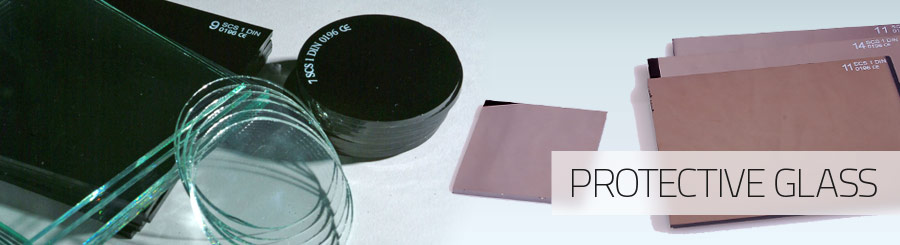

Welding filters are used for protection of eyes against ultraviolet and infrared radiation which originates during the process of welding. Depending on the welding method and welder’s preference, filters of a different level of protection are used. The shading range is 3 – 14. Every filter is marked with a manufacturer’s brand, type of protection level, CE mark and DIN CERTO identification number. The protective filters, due to safety reasons as well as appropriate visibility, should be used along with colorless glass panels protecting both sides, they should be without surface defects such as: bubbles, scratches, inclusions, fogging, surface deformations, etc. Damaged filters or filters with defects should be replaced immediately. The filters used should be clean on the surface, without any tarnish of dust, greasy stains, dirt, etc. Dirty filters should be cleaned by means of a clean, soft cloth and if there is a durable dirt, they should be washed by means of liquid detergents, wiped thoroughly and dried. While using them, it should be remembered that they are made of glass and have cutting edges. Thus, they should be held in one’s fingers in the way so as not to hurt oneself.

The filters are made of mineral glass which does not cause any allergic reactions.

They should be stored in dry places and protected against dirt.

Welding filters are made according to DIN EN 166 and DIN EN 169 standards as well as the directive of the European Union number 89/686/EEC.